Ghid complet pentru cablarea senzorului fotoelectric și depanarea

Indiferent dacă sunteți un inginer cu experiență sau un nou în domeniul automatizării, veți găsi informații valoroase pentru a vă asigura că senzorii dvs. funcționează în mod fiabil și eficient.

Cuprins

Ce sunt senzorii fotoelectrici și cum funcționează?

Senzorii fotoelectrici sunt componente esențiale în sistemele moderne de automatizare industrială. Aceste dispozitive folosesc fascicule de lumină pentru a detecta obiecte și pentru a declanșa ieșirile corespunzătoare. Există mai multe tipuri de senzori fotoelectrici:

- Senzori cu fascicul transversal: Constă din emițător și unități receptor separate

- Senzori retroreflectorizanți: Folosiți un reflector pentru a respinge fasciculul de lumină

- Senzori difuzi: Detectează obiecte pe baza reflexiei directe

Alegerea tipului de senzor depinde de cerințele specifice ale aplicației, de domeniul de detectare și de condițiile de mediu.Aflați mai multe despre senzorii industriali

Pași esențiali pentru cablarea corectă a senzorului fotoelectric

Cablajul corect este esențial pentru funcționalitatea fiabilă a senzorului. Iată o detaliere a procesului de cablare:

- Conexiune de alimentare

- Conectați firul maro la pozitivul de 24 de volți DC

- Conectați firul albastru la negativul de 24 de volți DC

- Cablaj de ieșire

- Fir negru: Semnal de ieșire către intrarea PLC

- Fir alb: ieșire suplimentară (pentru modele cu ieșiri complementare)

„Codificarea corectă a culorilor și verificarea conexiunii sunt pași esențiali în prevenirea problemelor legate de cablare.” – Expert în automatizări industriale

Cum să configurați și să vă configurați senzorul fotoelectric?

Configurarea corectă asigură performanțe optime ale senzorului. Urmați acești pași de configurare:

- Montare și aliniere

- Fixați senzorul și reflectorul/receptorul pe suporturi stabile

- Asigurați-vă alinierea corectă între componente

- Mențineți intervalul de detecție recomandat

- Reglarea sensibilității

- Utilizați potențiometrul pentru a regla sensibilitatea

- Testați detectarea cu obiecte țintă reale

- Verificați funcționarea corectă a luminilor indicatoare

Probleme comune de depanare și soluții

| Emisiune | Cauza posibila | Soluţie |

|---|---|---|

| Fără semnal de ieșire | Cablare incorectă | Verificați conexiunile cablurilor |

| Declanșatoare false | Sensibilitate prea mare | Reglați potențiometrul |

| Detectare inconsistentă | Aliniere slabă | Realiniați componentele senzorului |

| Fără putere | Alimentare defectă | Verificați nivelurile de tensiune |

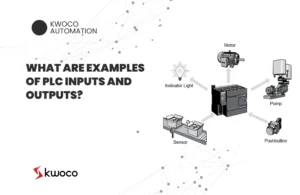

Integrare cu PLC și sisteme de control

Senzorii fotoelectrici moderni se integrează perfect cu controlere logice programabile (PLC) și alte sisteme de control. Considerațiile cheie includ:

- Compatibilitate semnal de intrare/ieșire

- Cerințe de timp de răspuns

- Protocoale de comunicare

- Configurarea sistemului

Întrebări frecvente

Începeți cu sensibilitate medie și ajustați în funcție de proprietățile obiectului țintă și de condițiile de mediu

Intervalele variază în funcție de model, dar se extind de obicei de la câțiva metri la peste 20 de metri

Utilizați setările adecvate de sensibilitate, mențineți optica curată și asigurați o montare stabilă

Pot fi necesare modele speciale concepute pentru detectarea obiectelor transparente.

Se recomandă curățarea regulată a suprafețelor optice și verificarea periodică a alinierii.

Alimentați-vă proiectele cu senzori Omron, Keyence, Schneider noi, originali – în stoc, gata acum!

Concluzie

- Verificați întotdeauna tensiunea corectă și conexiunile cablajului

- Montarea și alinierea corespunzătoare sunt cruciale pentru o funcționare fiabilă

- Întreținerea regulată asigură o performanță constantă

- Alegeți tipul de senzor potrivit pentru aplicația dvs

- Documentați setările de configurare pentru referințe viitoare

- Păstrați suprafețele optice curate și protejate

- Luați în considerare factorii de mediu în alegerea senzorului

Obțineți asistență de specialitate pentru nevoile dvs. de automatizare

Căutați senzori noi, originali pentru proiectele dvs.? La Kwoco, stocăm cei mai noi senzori de la mărci de top precum Omron, Keyence, și Schneider. Cumpărați cu încredere - livrare rapidă, calitate garantată! Cumpărați acum

Contactaţi-ne

Doar completați numele dvs., adresa de e-mail și o scurtă descriere a solicitării dvs. în acest formular. Vă vom contacta în termen de 24 de ore.

Categoria de produs

Produse de vânzare fierbinte

De asemenea, puteți găsi aceste subiecte interesante

Înțelegerea senzorilor fotoelectrici și a aplicațiilor acestora

Senzorii fotoelectrici sunt omniprezenti în automatizarea industrială modernă, acționând ca „ochii” multor sisteme. Acestea oferă o detectare crucială fără contact a obiectelor, impactând totul, de la sisteme simple de bandă transportoare până la linii de asamblare robotizate complexe. Acest articol se va scufunda adânc în lumea senzorilor fotoelectrici, explorând diferitele tipuri, principii de lucru și diverse aplicații ale acestora. Dacă sunteți implicat în producția de mașini, soluții din fabrică sau automatizare industrială generală, înțelegerea acestor senzori este esențială pentru optimizarea proceselor și asigurarea unei funcționări eficiente și fiabile. Această lectură vă va oferi această înțelegere.

Care sunt exemplele de intrări și ieșiri PLC?

Care sunt exemplele de intrări și ieșiri PLC? În automatizarea industrială, sistemele PLC (controller logic programabil) sunt creierul din spate

Interconectivitate PLC: Construirea unei punți între silozuri de date pentru o producție inteligentă

În contextul creșterii numărului de sisteme de automatizare industrială, complexitatea acestora devine semnificativ sporită, iar PLC-urile independente nu mai sunt suficiente pentru a satisface nevoile de producție în continuă creștere.

Interconectivitatea fiabilă și de încredere între PLC-uri a devenit esențială pentru a elimina silozurile de informații și a permite o producție inteligentă.