Шта је магнетни контактор и за шта се користи?

Садржај

Шта је магнетни контактор?

Магнетни контактор је електрични контролисани прекидач који се користи за пребацивање електричног струјног кола. То је посебан тип релеја дизајниран да поднесе већу струјну носивост. За разлику од једноставног прекидача, магнетни контактор се може даљински контролисати и способан је да поднесе велике струје.

Контактор је електромеханички уређај који ствара или прекида везу између напајања и оптерећења. Када је завојница под напоном, ствара магнетно поље које узрокује да се језгро контактора помера, затварајући контакте и дозвољавајући струји да тече.

Контактори се користе у широком спектру апликација, од управљања електромоторима до управљања великим инсталацијама осветљења. Они су кључни у индустријској аутоматизацији, нудећи поуздано средство за контролу кола велике снаге.

Њихова способност даљинског управљања чини их идеалним за сложене системе управљања где је ручни рад непрактичан или небезбедан. Магнетни контактори се обично користе у индустријским контролним производима и производним погонима. Они обезбеђују да машине и опрема раде безбедно и ефикасно.

Које су различите врсте магнетних контактора?

Постоји неколико типова магнетних контактора, од којих је сваки дизајниран за специфичне примене. Један уобичајени тип је АЦ магнетни контактор, који се користи у системима наизменичне струје. Други је ДЦ магнетни контактор, који ради у окружењима једносмерне струје.

Контактори су такође категорисани према њиховим тренутним снагама, у распону од неколико ампера до хиљада ампера. Избор контактора зависи од специфичних захтева електричног система.

Типови магнетних контактора укључују контакторе отвореног оквира и затворене контакторе. Контактори отвореног оквира се користе у панелима где су заштићени од околине, док су затворени контактори погодни за самосталне примене.

Додатно, контактори се могу класификовати на основу броја полова које имају, као што су једнополни, двополни и трополни контактори. Сваки тип служи различитој сврси и бира се на основу специфичних потреба апликације. на пример, Сцхнеидер ПЛЦ често користи специјализоване контакторе прилагођене њиховим системима.

Који је принцип рада магнетног контактора?

Принцип рада магнетног контактора укључује употребу електромагнета за контролу отварања и затварања електричних контаката. Када се напон примени на завојницу контактора, ствара се магнетно поље. Ово поље привлачи покретно језгро контактора, које заузврат затвара контакте.

Када је намотај контактора под напоном, контакти се затварају, дозвољавајући струји да тече до оптерећења. Супротно томе, када је контактор без напона, магнетно поље нестаје, а контакти се отварају, прекидајући проток струје.

Овај принцип рада магнетног контактора омогућава даљинску контролу кола велике снаге. Такође обезбеђује средство за заштиту контролног кола од великих струја у струјном колу.

Способност контактора да брзо отвори и затвори струјно коло чини га битном компонентом у сигурносним и контролним системима. Контактори су дизајнирани да подносе велике ударне струје које се јављају приликом покретања мотора, што их чини незаменљивим у индустријским окружењима.

Како ради магнетни контактор у индустријским апликацијама?

У индустријским окружењима, магнетни контактор функционише тако што управља снагом која се испоручује тешким машинама. Када се прими стартни сигнал, намотај контактора је под напоном. Ово ствара магнетно поље, увлачећи језгро контактора и затварајући главне контакте.

Ово омогућава струји да тече до мотора или другог оптерећења, започињући његов рад. Када се да сигнал за заустављање, калем се искључује, магнетно поље колабира, а контакти се отварају, заустављајући проток електричне енергије.

Магнетни контактори су кључни у контроли електромотора, система осветљења и других оптерећења велике снаге. Они пружају поуздан начин за покретање и заустављање опреме, штите од преоптерећења и обезбеђују сигуран рад.

Примена технологије магнетног контактора протеже се на различите индустрије, укључујући производњу, ХВАЦ и руковање материјалима. На пример, у производном погону, контактори могу да контролишу рад транспортних трака, пумпи и других машина, обезбеђујући несметане и ефикасне производне процесе.

Које су кључне карактеристике магнетних контактора?

Магнетни контактори долазе са различитим карактеристикама које их чине погодним за различите примене. Једна кључна карактеристика је њихова способност да подносе велику струју. Контактори су дизајнирани да пребацују струје у распону од неколико ампера до хиљада ампера, што их чини идеалним за апликације у тешким условима.

Још једна важна карактеристика је њихова могућност даљинске контроле. Ово омогућава оператерима да управљају опремом са безбедне удаљености, смањујући ризик од електричних несрећа.

Карактеристике контактора такође укључују њихову издржљивост и поузданост. Направљени су да издрже тешка индустријска окружења и честе операције пребацивања. Многи контактори такође имају помоћне контакте, који се могу користити за сигнализацију или блокаду.

Ови помоћни контакти пружају додатне опције управљања, побољшавајући функционалност контактора. На пример, помоћни контакт се може конфигурисати као нормално отворен или нормално затворен, пружајући флексибилност у управљачким круговима.

Која је структура магнетног контактора?

Структура магнетног контактора састоји се од неколико кључних компоненти. Завојница је срце контактора, одговорна за стварање магнетног поља које управља уређајем. Језгро је покретни део који привлачи калем када је под напоном, што доводи до затварања контаката.

Контакти су делови који стварају или прекидају електричну везу. Обично постоје три типа контаката у контактору: контакти за напајање, помоћни контакти и контакти намотаја.

Друга важна компонента је систем за сузбијање лука. Када се контактор отвори, између контаката се може формирати електрични лук. Систем за сузбијање лука помаже у брзом гашењу овог лука, спречавајући оштећење контаката и осигуравајући поуздан рад.

Кућиште контактора обезбеђује физичку заштиту и изолацију за унутрашње компоненте. Све у свему, дизајн магнетног контактора је оптимизован за издржљивост, поузданост и безбедност.

Које су разлике између контактора и релеја?

Контактори и релеји су и електромеханички прекидачи, али се користе у различитим апликацијама и имају различите карактеристике. Контактор је дизајниран да носи већи капацитет струје од релеја.

Контактори се обично користе у апликацијама које укључују електричне моторе, системе осветљења и друга оптерећења велике снаге. Насупрот томе, релеји се користе за апликације ниже струје и често се налазе у контролним круговима.

Још једна кључна разлика је присуство функција за сузбијање лука у контакторима. Због великих струја којима рукују, контактори су опремљени луковима и другим механизмима за брзо гашење електричних лука.

Релеји, с друге стране, обично немају ове карактеристике. Поред тога, контактори често имају више контаката, укључујући и контакте за напајање и помоћне контакте, док релеји обично имају мање контаката. Табела у наставку сумира неке од главних разлика:

| Феатуре | Цонтацтор | Штафета |

|---|---|---|

| Цуррент Цапацити | Висока (Ампери до хиљаде Ампера) | Ниска (обично неколико ампера) |

| Апликација | Електрични мотори, оптерећења велике снаге | Контролна кола, апликације мале снаге |

| Супресија лука | Да | бр |

| Број контаката | Вишеструко (напајање и помоћно) | Мање |

| Волтаге | Висок напон | Лов Волтаге |

| Типична употреба | Индустријска аутоматизација, дистрибуција електричне енергије | Пребацивање сигнала, контролне табле |

Како се магнетни контактори носе са сузбијањем лука?

Потискивање лука је критичан аспект дизајна магнетног контактора. Када се контактор отвори под оптерећењем, између контаката се може формирати електрични лук.

Овај лук може произвести значајну топлоту и оштетити контакте ако се брзо не угаси. Контактори користе различите методе за сузбијање лука, укључујући лукове, магнетне издувавање и посебне контактне материјале.

Лучни жлебови су структуре које помажу да се лук подели и охлади, што доводи до његовог брзог гашења. Магнетно издувавање користи магнетно поље да одгурне лук од контаката и уђе у отвор за лук.

Специјални контактни материјали, као што су легуре сребра, се користе да би се минимизирали ефекти лука и продужили век трајања контаката. Правилно гашење лука је од суштинског значаја за обезбеђивање поузданог и безбедног рада контактора у апликацијама велике струје.

Како функционишу контактори у системима наизменичне и једносмерне струје?

Контактори могу бити дизајнирани да раде и у АЦ и ДЦ системима, али постоје неке разлике у њиховом дизајну и раду. Магнетни контактори наизменичне струје су дизајнирани да управљају наизменичном струјом, која природно прелази нулти напон много пута у секунди.

Ово помаже да се угаси лук када се контакти отворе. АЦ контактори обично користе ламинирано језгро како би се минимизирали губици вртложних струја.

ДЦ магнетни контактори, с друге стране, морају да раде са континуираним током струје, која природно не прелази нулу. Ово чини гашење лука изазовнијим. ДЦ контактори често користе робусније методе за сузбијање лука, као што су магнетно издувавање, да би се обезбедио поуздан рад.

Поред тога, дизајн намотаја се може разликовати између АЦ и ДЦ контактора како би се оптимизовале перформансе за сваки тип струје. на пример, Омрон ПЛЦ системи користе и АЦ и ДЦ контакторе у зависности од захтева апликације.

Зашто одабрати Квоцо-ова решења за индустријску аутоматизацију?

У Квоцо-у смо специјализовани за пружање висококвалитетних решења за индустријску аутоматизацију прилагођених потребама фабрика машина и опреме, произвођача и компанија за фабричка решења.

Наш широк асортиман производа укључује магнетне контакторе, релеје, ПЛЦ-ови, ХМИ, инвертера, и друге битне компоненте за индустријске системе управљања. Разумемо критичну улогу коју поуздана опрема игра у вашим операцијама и посвећени смо испоруци производа који испуњавају највише стандарде квалитета и перформанси.

Одабир Квоцо-а значи партнерство са компанијом која има дубоко разумевање пејзажа индустријске аутоматизације. Наш тим стручњака је посвећен томе да вам пружи најбоља решења за ваше специфичне потребе.

Нудимо свеобухватну подршку, од избора производа до инсталације и одржавања, осигуравајући да ваши системи раде неометано и ефикасно. Уз Квоцо, можете веровати да добијате врхунске производе и услугу без премца, подржане дугогодишњим искуством и посвећеношћу изврсности.

Често постављана питања

Главна функција магнетног контактора је да укључује и искључује струјна кола. Дизајниран је да поднесе велике струје и може се даљински контролисати, што га чини идеалним за индустријску примену.

Магнетни контактор је дизајниран за већи капацитет носивости струје и обично укључује функције за сузбијање лука, док се релеј користи за апликације са нижим струјама и можда неће имати супресију лука.

Кључне компоненте магнетног контактора укључују завојницу, језгро, контакте (напајање, помоћни и калем) и систем за гашење лука. Ове компоненте раде заједно да контролишу проток електричне енергије.

Пригушивање лука је важно у контакторима јер помаже да се брзо угасе електрични лукови који се могу формирати када се контакти отворе. Ово спречава оштећење контаката и обезбеђује поуздан рад.

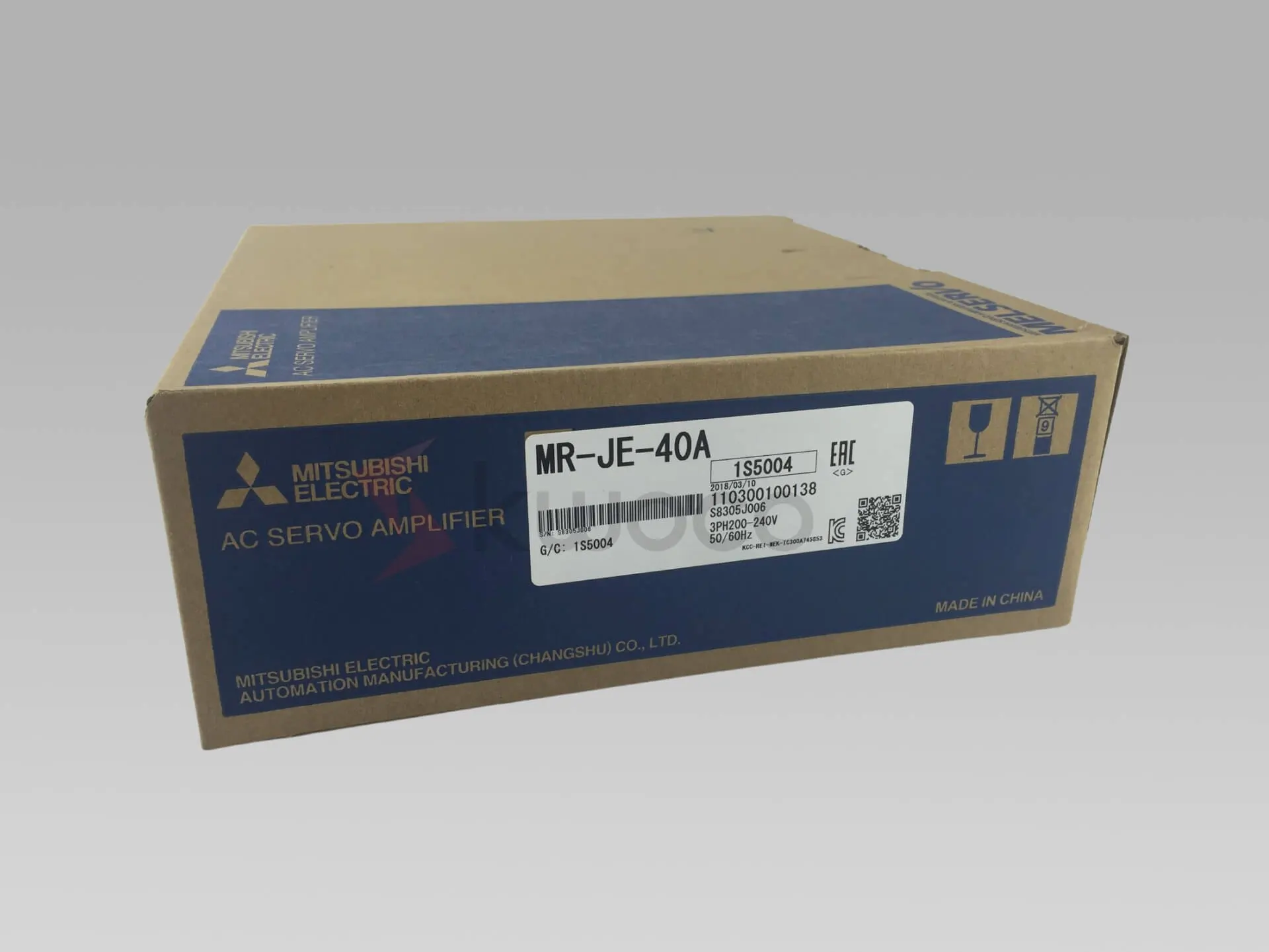

Магнетни контактори се користе у широком спектру индустрија, укључујући производњу, ХВАЦ, руковање материјалима и било коју индустрију која захтева контролу електричних оптерећења велике снаге. на пример, Митсубисхи ПЛЦ системи се широко користе у овим индустријама, често укључују магнетне контакторе.

Напајајте своје пројекте са потпуно новим, оригиналним Омрон, Митсубисхи, Сцхнеидер ПЛЦ – на лагеру, спремни одмах!

Закључак

- Магнетни контактори су неопходни за контролу електричних кола велике снаге у индустријским окружењима.

- Долазе у различитим типовима, укључујући АЦ и ДЦ верзије, и категорисани су према струјним оценама и конфигурацији полова.

- Принцип рада магнетног контактора укључује коришћење електромагнета за отварање и затварање контаката, омогућавајући даљинску контролу струјних кола.

- Кључне карактеристике укључују управљање великом струјом, могућност даљинског управљања, издржљивост и присуство помоћних контаката за додатне опције контроле.

- Контактори се разликују од релеја првенствено по свом тренутном капацитету руковања и карактеристикама гашења лука.

- Гашење лука је кључно за спречавање оштећења контакта и осигуравање поузданог рада.

- Избор поузданог добављача као што је Квоцо обезбеђује приступ висококвалитетним производима и стручну подршку за ваше потребе индустријске аутоматизације.

Запамтите, разумевање функције и примене магнетних контактора може значајно побољшати ефикасност и безбедност ваших индустријских операција. За више информација о нашим производима и услугама, слободно контактирајте нас данас.

Контактирајте нас

Само попуните своје име, адресу е-поште и кратак опис вашег упита у овом обрасцу. Контактираћемо вас у року од 24 сата.

Ове теме могу такође бити интересантне

Разумевање аналогних улаза у ПЛЦ системима: Премошћивање јаза између дигиталних и аналогних сигнала

Аналогни улази су спас савремених система аутоматизације, делујући као кључна веза између физичких процеса и дигиталних контролера као што су ПЛЦ (програмабилни логички контролери). Разумевање концепта аналогних улаза и тога како се они разликују од дигиталних улаза је од суштинског значаја за свакога ко је укључен у индустријску аутоматизацију. Овај чланак ће се бавити тиме шта су аналогни улази, како функционишу у ПЛЦ системима и зашто је разумевање разлика између аналогних и дигиталних сигнала од виталног значаја.

Најбољи произвођачи ПЛЦ-а: Најбољи брендови програмабилних логичких контролера

Програмабилни логички контролери (ПЛЦ) су срце модерне индустријске аутоматизације. Они контролишу машине, процесе и фабричке монтажне линије, чинећи операције ефикаснијим и поузданијим. Овај чланак урања у свет произвођача ПЛЦ-ова, истражујући водеће брендове ПЛЦ-а који напајају индустрију широм света. Било да сте нови у аутоматизацији или желите да надоградите своје системе, разумевање најбољих играча на ПЛЦ тржишту је од суштинског значаја.

Који се ПЛЦ најчешће користи у индустрији? Објашњени врхунски ПЛЦ-ови

У индустрији аутоматизације која се стално развија, једно питање се често поставља: Који се програмибилни логички контролер (ПЛЦ) највише користи у индустријским апликацијама? Разумевање пејзажа произвођача ПЛЦ-а и њихове понуде може помоћи професионалцима да донесу информисане одлуке за своје потребе аутоматизације. Овај чланак истражује најпопуларније брендове ПЛЦ-а, њихове карактеристике и зашто доминирају у сектору индустријске аутоматизације.