Memilih Blok Terminal yang Tepat: Panduan Lengkap

Memahami jenis-jenis utama, pertimbangan listrik dan mekanik, peringkat keamanan, dan faktor desain tambahan sangat penting untuk membuat pilihan yang tepat. Panduan ini membahas semua yang perlu Anda ketahui untuk memilih blok terminal yang ideal untuk kebutuhan Anda.

Daftar isi

Apa itu Blok Terminal?

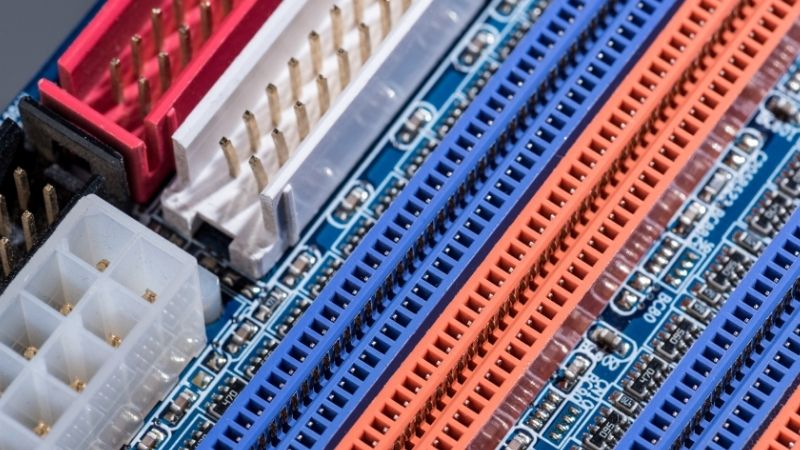

Blok terminal adalah rumah modular dan terisolasi yang dirancang untuk menghubungkan beberapa kabel dengan aman, sering digunakan dalam sistem industri dan listrik yang membutuhkan koneksi yang andal dan terorganisasi dengan baik. Blok ini mencakup komponen penjepit yang menahan kabel pada tempatnya, sering kali menyediakan cara mudah untuk menukar koneksi selama pemeriksaan atau perawatan.

Umumnya dikenal sebagai koneksi terminal, terminal sekrup, atau sekadar konektor, blok terminal merupakan hal pokok dalam menciptakan solusi manajemen kabel yang aman dan efektif dalam sistem yang kompleks.

Jenis-jenis Blok Terminal

Blok terminal tersedia dalam berbagai gaya, masing-masing sesuai untuk aplikasi yang berbeda. Berikut ini adalah rincian beberapa jenis yang paling umum:

Blok Terminal Pemasangan PCB: Dikenal sebagai blok terminal wire-to-board, blok ini dipasang langsung ke PCB (papan sirkuit tercetak). Blok ini mengamankan kabel melalui mekanisme penjepit dan sering digunakan dalam perangkat elektronik dan perangkat yang lebih kecil.

Strip Penghalang: Jenis ini menggunakan metode sekrup untuk menahan terminal cincin atau sekop, sehingga menyediakan sambungan aman yang dapat menahan getaran. Strip penghalang ideal dalam aplikasi yang memerlukan keandalan dalam kondisi gerakan atau guncangan.

Blok Terminal Rel DIN: Dipasang pada rel DIN standar, blok serbaguna ini cocok untuk sambungan kabel ke kabel atau ground. Blok ini banyak digunakan dalam panel kontrol industri dan sistem otomasi karena kemudahan pemasangan dan konfigurasi modularnya.

Setiap jenis menawarkan fitur yang unik, dan pemilihan jenis yang tepat bergantung pada persyaratan sistem dan lingkungan instalasi Anda.

Pertimbangan Listrik Utama untuk Blok Terminal

Saat memilih blok terminal, penting untuk mengevaluasi parameter kelistrikan untuk memastikan kompatibilitas dengan sistem Anda:

Peringkat Saat Ini: Ini menentukan arus maksimum yang dapat ditangani blok tanpa terlalu panas. Selalu pilih blok dengan nilai setidaknya 1,5 kali arus maksimum yang diharapkan dalam sistem Anda untuk mencegah terlalu panas dan potensi kegagalan.

Peringkat Tegangan: Tegangan maksimum yang dapat dikelola blok terminal dengan aman bergantung pada bahan dan kemiringan blok. Pastikan peringkat blok melebihi tegangan sistem Anda untuk mencegah kerusakan isolasi atau masalah lainnya.

Ukuran Kawat: Pastikan blok terminal mendukung rentang ukuran kawat yang digunakan dalam aplikasi Anda, dari kawat pilin hingga kawat inti padat, karena blok yang berbeda kompatibel dengan ukuran kawat tertentu.

Pertimbangan kelistrikan sangat penting untuk memastikan blok dapat menahan tuntutan aplikasi Anda tanpa mengorbankan keselamatan.

Pertimbangan Mekanik Utama untuk Blok Terminal

Desain fisik blok terminal juga memainkan peran penting dalam kesesuaiannya untuk berbagai instalasi. Berikut ini adalah beberapa aspek mekanis yang penting:

Orientasi Masuk Kawat: Blok terminal biasanya tersedia dengan orientasi horizontal, vertikal, atau 45 derajat, memberikan fleksibilitas berdasarkan ruang pemasangan dan kendala tata letak.

Metode Pengamanan Kawat: Metode pengamanan utama meliputi terminal sekrup, klem tekan, dan klem pegas. Setiap jenis menawarkan keseimbangan kekuatan, kemudahan penggunaan, dan kompatibilitas yang unik dengan jenis kawat.

Tipe Modul: Beberapa blok saling terkait, yang memungkinkan konfigurasi khusus dengan menyambungkan beberapa modul bersama-sama, sementara yang lain berupa satu bagian, yang menyediakan jumlah kutub tetap.

Pertimbangan desain mekanis membantu memastikan blok terminal terintegrasi secara mulus ke sistem Anda sekaligus memungkinkan akses, pemasangan, dan pemeliharaan yang mudah.

Peringkat dan Sertifikasi Keamanan

Keselamatan merupakan prioritas utama, terutama dalam sistem bertegangan tinggi atau arus tinggi. Blok terminal sering kali disertifikasi sesuai standar UL (Underwriters Laboratories) atau IEC (International Electrotechnical Commission), dengan banyak blok yang terbuat dari bahan yang memenuhi peringkat mudah terbakar UL94V-0. Saat memilih blok terminal, pastikan blok tersebut mematuhi sertifikasi keselamatan yang dipersyaratkan oleh proyek Anda, karena sertifikasi ini memastikan blok tersebut dapat mengatasi potensi bahaya.

Memiliki blok terminal bersertifikat tidak hanya meningkatkan keselamatan instalasi Anda tetapi juga memastikan kepatuhan terhadap standar industri.

Pertimbangan Desain Tambahan

Selain faktor listrik dan mekanik, pilihan desain tertentu dapat meningkatkan kegunaan dan efektivitas blok terminal Anda:

Kode Warna dan Penandaan: Rumah berwarna atau blok berlabel menyederhanakan pemasangan dan pemeliharaan, terutama pada sistem dengan banyak sirkuit dan sambungan.

Toleransi Suhu: Beberapa aplikasi mengharuskan blok terminal untuk menahan suhu ekstrem. Blok dengan peringkat suhu tinggi memastikan keandalan di lingkungan seperti itu.

Elemen desain tambahan ini dapat menyederhanakan perakitan dan meningkatkan pemeliharaan jangka panjang, membantu Anda menciptakan sistem yang terorganisir dengan baik dan tangguh.

Dukung proyek Anda dengan terminal Omron, Mitsubishi, Schneider baru dan asli– tersedia dan siap sekarang!

Kesimpulan

Memilih blok terminal yang tepat sangat penting untuk manajemen kabel yang aman dan efisien. Dengan memahami berbagai jenis blok terminal, menilai pertimbangan utama kelistrikan dan mekanik, memastikan kepatuhan terhadap standar keselamatan, dan mempertimbangkan peningkatan desain, Anda dapat membuat pilihan yang tepat. Blok terminal yang dipilih dengan baik tidak hanya akan memenuhi kebutuhan Anda saat ini, tetapi juga berkontribusi pada sistem kelistrikan yang andal dan dapat dirawat dari waktu ke waktu.

Jika Anda mencari pemasok blok terminal industri yang andal, hubungi Kwoco. Kami menyediakan terminal baru dan asli dari merek-merek ternama seperti Omron Dan Bahasa Inggris Schneider, dengan pengiriman global tersedia untuk memenuhi kebutuhan Anda.

Hubungi kami

Cukup isi nama, alamat email, dan deskripsi singkat pertanyaan Anda dalam formulir ini. Kami akan menghubungi Anda dalam waktu 24 jam.

Kategori Produk

Produk Penjualan Panas

Anda Mungkin Juga Menemukan Topik Ini Menarik

Master Ladder Logic: Apa yang Perlu Anda Ketahui

Sebagai seorang teknisi di Kwoco, saya sering ditanya, “Apa sebenarnya Ladder Logic untuk PLC? Apakah sulit untuk mempelajarinya?” Jangan khawatir. Hari ini, saya akan memandu Anda melalui keterampilan yang penting dan mendasar ini.

5 Jenis Encoder pada Motor Servo yang Perlu Anda Ketahui

Sebagai seorang insinyur dengan pengalaman luas dalam otomasi industri, saya memiliki pemahaman mendalam tentang motor servo dan enkoder yang digunakannya. Sistem servo banyak digunakan dalam otomasi, dengan enkoder yang berfungsi sebagai komponen utama untuk mengendalikan kecepatan dan posisi secara akurat.

Pemrograman PLC: Panduan Lengkap untuk Pemula

Di dunia saat ini, di mana otomasi industri dan produksi cerdas sedang berkembang pesat, Pengontrol Logika Terprogram (PLC) telah menjadi "inti" dari setiap sistem otomatis. Bagi individu dan perusahaan yang ingin memasuki atau berkembang di bidang otomasi, menguasai program PLC bukan sekadar keterampilan—melainkan kunci masa depan.