5 Jenis Encoder pada Motor Servo yang Perlu Anda Ketahui

- kwoco-plc.com

- 12 Oktober 2024

- 19:27 WIB

Dalam artikel ini, saya akan menguraikan berbagai jenis encoder yang digunakan dalam motor servo dengan cara yang sederhana dan mudah dipahami.

Daftar isi

Mengapa Encoder Penting dalam Motor Servo?

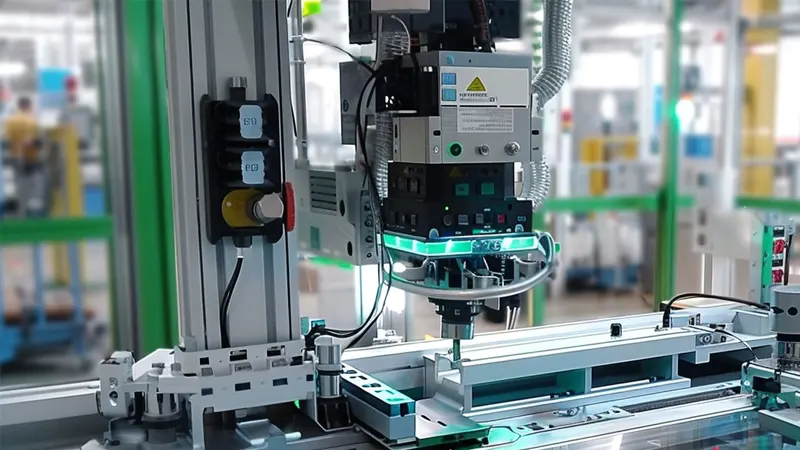

Tidak seperti motor stepper, motor servo memerlukan kontrol loop tertutup, yang terus-menerus menerima sinyal umpan balik untuk mengendalikan kecepatan, sudut, dan posisi secara tepat. Encoder bertindak sebagai mata sistem servo, memantau pergerakan motor secara real-time dan memastikannya mengikuti instruksi yang diberikan secara akurat.

Tanpa encoder, kontrol motor servo akan menjadi tidak tepat. Encoder sangat penting dalam lingkungan yang kompleks seperti jalur produksi otomatis Dan robot medis, membantu menghindari kesalahan dan memastikan efisiensi dan keselamatan operasional.

1. Encoder Inkremental

Encoder inkremental membutuhkan titik acuan setiap kali mereka mulai merekam perubahan gerakan. Mereka cocok untuk aplikasi yang tidak memerlukan pelacakan posisi presisi tinggi, seperti jalur pengemasan atau peralatan gudang.

Fitur:

- Memerlukan kepulangan setelah setiap siklus daya.

- Terutama digunakan untuk pemantauan kecepatan, posisi tidak tepat.

| Perbandingan | Kelebihan | Kontra |

|---|---|---|

| Kasus penggunaan | Biaya rendah, fleksibilitas tinggi | Perlu kalibrasi ulang setelah kehilangan daya |

| Sinyal umpan balik | Pemantauan kecepatan waktu nyata | Tidak dapat melacak posisi secara langsung |

2. Pengkode Absolut

Encoder absolut mempertahankan data posisi terkini bahkan setelah kehilangan daya, menghilangkan kebutuhan untuk homing. Mereka umumnya digunakan dalam robot bedah atau robot pembuat mobil, memastikan peralatan dapat melanjutkan operasinya tanpa kesalahan setelah dihidupkan ulang.

Fitur:

- Memberikan ketepatan pelacakan posisi.

- Memastikan dimulainya kembali proses restart yang lancar setelah terjadi kegagalan daya atau gangguan sistem.

| Kasus penggunaan | Aplikasi Umum |

|---|---|

| Tugas presisi tinggi | Peralatan medis, otomatisasi presisi |

3. Pengkode Linier

Encoder linier memantau gerakan garis lurus, seperti di mesin pemotong laser atau sistem penyortiran otomatisMereka memastikan posisi yang tepat bahkan pada kecepatan tinggi, menjadikannya ideal untuk lingkungan yang menuntut kecepatan dan akurasi.

4. Encoder Putar

Encoder putar memantau putaran poros, mengubah arah pergerakan poros menjadi sinyal digital yang dapat ditafsirkan oleh sistem kontrol untuk kecepatan dan posisi.

Encoder putar sering diintegrasikan ke motor untuk memberikan umpan balik yang akurat, bahkan selama operasi berkecepatan tinggi.

5. Encoder Optik, Magnetik, dan Kapasitif

Encoder juga diklasifikasikan berdasarkan teknologi penginderaannya:

- Encoder optik: Presisi tinggi namun sensitif terhadap debu.

- Encoder magnetik: Anti-interferensi yang kuat, cocok untuk lingkungan yang keras.

- Encoder kapasitif: Cepat dan terjangkau tetapi kurang presisi dibandingkan enkoder optik.

Bagaimana Cara Memilih Encoder untuk Motor Saya?

Berikut adalah faktor-faktor utama yang perlu dipertimbangkan saat memilih encoder:

Mengidentifikasi Kebutuhan Aplikasi

Memilih encoder absolut jika Anda perlu memantau posisi yang tepat. Gunakan encoder tambahan jika pemantauan kecepatan merupakan persyaratan utama.Pertimbangkan Faktor Lingkungan

Di lingkungan yang berdebu atau lembab, encoder magnetik atau yang memiliki peringkat IP tinggi (misalnya, IP68) lebih cocok. Untuk tugas presisi tinggi, encoder optik direkomendasikan.Kemampuan Pemulihan Daya

Jika sistem harus menyimpan data posisi setelah pemadaman listrik, encoder absolut sangatlah penting.Persyaratan Akurasi dan Resolusi

Aplikasi seperti Mesin CNC atau robot medis memerlukan encoder beresolusi tinggi (misalnya, encoder absolut 24-bit). Aplikasi yang tidak terlalu menuntut dapat menggunakan encoder beresolusi rendah.Kompatibilitas Antarmuka dan Komunikasi

Pastikan antarmuka encoder (misalnya, RS485, CAN bus, atau analog) cocok dengan sistem kendali Anda.Kemudahan Instalasi dan Perawatan

Desain modular yang mudah dipasang dan dirawat dapat meningkatkan efisiensi dalam sistem otomasi yang kompleks.

Pertanyaan Umum tentang Motor Servo dan Encoder

1. Jenis Encoder Apa yang Digunakan pada Motor Servo?

Motor servo biasanya menggunakan bertambah bertahap Dan encoder absolutEncoder inkremental melacak pergerakan dan kecepatan relatif, sementara encoder absolut menyimpan data posisi yang tepat bahkan saat daya mati.

2. Apa saja tiga jenis dasar encoder?

Encoder Inkremental: Melacak pergerakan relatif dan membutuhkan homing.

Encoder Absolut: Menyimpan data posisi di seluruh siklus daya.

Encoder Putar dan Linear: Mengukur gerakan sudut dan linear, masing-masing.

3. Bisakah Motor Servo Berjalan tanpa Encoder?

Sementara beberapa sistem servo sederhana menggunakan kontrol loop terbuka, sebagian besar membutuhkan umpan balik loop tertutup untuk presisi. Menjalankan motor servo tanpa encoder dapat membahayakan kontrol kecepatan dan posisi.

4. Apa perbedaan antara encoder putar dan encoder linier?

Rotary Encoder: Mengukur sudut atau kecepatan putaran, biasanya digunakan pada poros motor.

Encoder Linear: Memantau perpindahan linear, ideal untuk pemotong laser atau mesin CNC.

Dukung proyek Anda dengan Omron, Mitsubishi, Schneider Servo baru dan asli – tersedia sekarang!

Kesimpulan

Pemilihan encoder yang tepat sangat penting untuk mengoptimalkan kecepatan, akurasi, dan keandalan pada motor servo. Untuk proyek yang membutuhkan keandalan tinggi, encoder absolut direkomendasikan, karena encoder ini mempertahankan data posisi bahkan setelah kehilangan daya. Meskipun harganya mungkin lebih mahal, encoder ini meningkatkan efisiensi dan keselamatan operasional.

Mencari servo baru dan asli untuk proyek Anda? Di Kwoco, kami menyediakan servo terbaru dari merek-merek ternama seperti Omron, Mitsubishi, Dan Bahasa Inggris SchneiderBerbelanja dengan percaya diri—pengiriman cepat, kualitas terjamin! Beli Sekarang

Hubungi kami

Cukup isi nama, alamat email, dan deskripsi singkat pertanyaan Anda dalam formulir ini. Kami akan menghubungi Anda dalam waktu 24 jam.

Kategori Produk

Produk Penjualan Panas

Anda Mungkin Juga Menemukan Topik Ini Menarik

Mengapa Memilih PLC Allen-Bradley untuk Proyek Anda?

Mengapa Memilih PLC Allen-Bradley untuk Proyek Anda? Kesulitan memilih PLC yang tepat untuk proyek rekayasa Anda? Anda tidak sendirian.

Penjelasan tentang Limit Switch: Jenis, Penggunaan, dan Prinsip Kerja

Sakelar pembatas merupakan komponen penting dalam berbagai perangkat dan mesin, yang berperan penting dalam mendeteksi keberadaan atau ketiadaan suatu objek. Baik itu pintu lemari es atau mesin industri, sakelar pembatas merupakan pahlawan di balik layar, yang menjalankan fungsi yang memastikan kelancaran dan keamanan pengoperasian.

Sensor jarak vs Sensor fotolistrik

Artikel ini membahas lebih mendalam tentang sensor jarak dan sensor fotolistrik, menjelajahi fungsi, perbedaan, dan aplikasinya. Baik Anda seorang insinyur berpengalaman di pabrik mesin dan peralatan atau penyedia solusi yang mencari komponen otomasi terbaik, memahami jenis sensor ini sangatlah penting. Sebagai pabrik manufaktur produk otomasi dan kontrol industri, kami hadir untuk menjelaskan seluk-beluk komponen penting ini, yang pada akhirnya memandu Anda menuju keputusan yang tepat untuk proyek Anda.