5 Types of Encoders in Servo Motors You Need to Know

- kwoco-plc.com

- October 12, 2024

- 7:27 pm

In this article, I will break down the different types of encoders used in servo motors in a simple and easy-to-understand way.

Table of Contents

Why Are Encoders Important in Servo Motors?

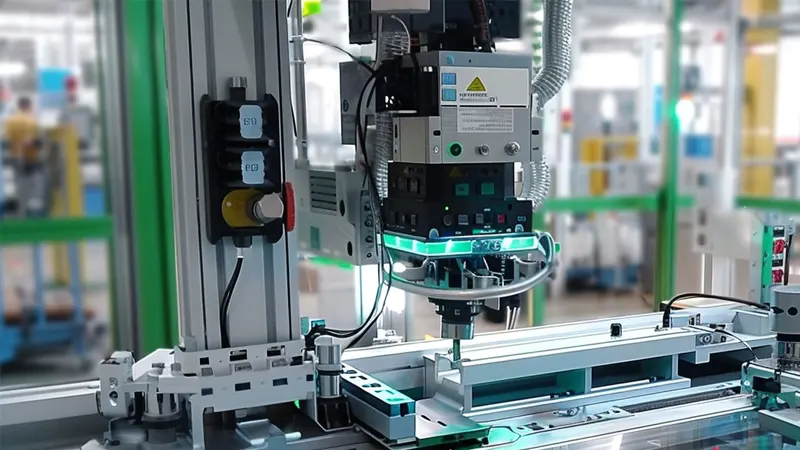

Unlike stepper motors, servo motors require closed-loop control, which continuously receives feedback signals to control speed, angle, and position precisely. Encoders act as the eyes of the servo system, monitoring the motor’s movement in real-time and ensuring it follows the given instructions accurately.

Without encoders, servo motor control would become imprecise. Encoders are crucial in complex environments like automated production lines and medical robots, helping avoid errors and ensuring operational efficiency and safety.

1. Incremental Encoder

Incremental encoders need a reference point each time they start to record movement changes. They are suitable for applications where high-precision position tracking isn’t required, such as packaging lines or warehouse equipment.

Features:

- Requires homing after each power cycle.

- Primarily used for speed monitoring, not precise positioning.

| Comparison | Pros | Cons |

|---|---|---|

| Use case | Low cost, high flexibility | Needs re-calibration after power loss |

| Feedback signal | Real-time speed monitoring | Cannot directly track position |

2. Absolute Encoder

Absolute encoders retain current position data even after power loss, eliminating the need for homing. They are commonly used in surgical robots or automobile manufacturing robots, ensuring the equipment can resume operations without errors after a restart.

Features:

- Provides precise position tracking.

- Ensures smooth restart after power failures or system disruptions.

| Use case | Typical Application |

|---|---|

| High-precision tasks | Medical equipment, precision automation |

3. Linear Encoder

Linear encoders monitor straight-line movements, such as in laser cutting machines or automated sorting systems. They ensure precise positioning even at high speeds, making them ideal for environments that demand both speed and accuracy.

4. Rotary Encoder

Rotary encoders monitor the rotation of shafts, converting the direction of the shaft’s movement into digital signals that control systems can interpret for speed and position.

Rotary encoders are often integrated into motors to provide accurate feedback, even during high-speed operations.

5. Optical, Magnetic, and Capacitive Encoders

Encoders are also classified by their sensing technologies:

- Optical encoders: High precision but sensitive to dust.

- Magnetic encoders: Strong anti-interference, suitable for harsh environments.

- Capacitive encoders: Fast and affordable but less precise than optical encoders.

How do I Choose an Encoder for my Motor?

Here are key factors to consider when selecting an encoder:

Identify Application Needs

Choose absolute encoders if you need to monitor exact positions. Use incremental encoders if speed monitoring is the primary requirement.Consider Environmental Factors

In dusty or humid environments, magnetic encoders or those with a high IP rating (e.g., IP68) are more suitable. For high-precision tasks, optical encoders are recommended.Power Recovery Capability

If the system must retain position data after a power outage, absolute encoders are essential.Accuracy and Resolution Requirements

Applications like CNC machines or medical robots require high-resolution encoders (e.g., 24-bit absolute encoders). Less demanding applications can use lower-resolution encoders.Interface and Communication Compatibility

Ensure the encoder’s interface (e.g., RS485, CAN bus, or analog) matches your control system.Ease of Installation and Maintenance

Modular designs that are easy to install and maintain can enhance efficiency in complex automation systems.

Common Questions about Servo Motors and Encoders

1. What Type of Encoder Is Used in a Servo Motor?

Servo motors typically use incremental and absolute encoders. Incremental encoders track relative movement and speed, while absolute encoders store precise position data even during power loss.

2. What Are the Three Basic Types of Encoders?

Incremental Encoder: Tracks relative movement and needs homing.

Absolute Encoder: Retains position data across power cycles.

Rotary and Linear Encoders: Measure angular and linear movements, respectively.

3. Can a Servo Motor Run without an Encoder?

While some simple servo systems use open-loop control, most require closed-loop feedback for precision. Running a servo motor without an encoder can compromise speed and position control.

4. What’s the Difference Between Rotary and Linear Encoders?

Rotary Encoder: Measures rotational angles or speeds, typically used on motor shafts.

Linear Encoder: Monitors linear displacement, ideal for laser cutters or CNC machines.

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

Selecting the right encoder is essential for optimizing speed, accuracy, and reliability in servo motors. For projects requiring high reliability, absolute encoders are recommended, as they maintain position data even after power loss. Although they may cost more, they enhance operational efficiency and safety.

Looking for new, original servos for your projects? At Kwoco, we stock the latest servos from top brands like Omron, Mitsubishi, and Schneider. Shop with confidence—fast shipping, guaranteed quality! Buy Now

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

You May Also Find These Topics Interesting

Variable Frequency Drives (VFD): Complete Guide to Motor Control

A comprehensive guide to variable frequency drives (VFDs) – the technology that’s revolutionizing motor control in industrial applications. Whether you’re an engineer, technician, or facility manager, this article will help you understand how VFDs work and why they’re crucial for modern motor applications.

Essential Components of PLCs Explained

Programmable Logic Controllers (PLCs) are at the heart of modern industrial automation. They serve as the control system that orchestrates machinery and processes in factories, plants, and other automated environments. Understanding the components of a PLC is crucial for anyone involved in the field, as it helps in designing, troubleshooting, and optimizing automated systems. This comprehensive guide will walk you through the key elements of a PLC, making complex concepts easy to grasp.

Cooperation Cases Between Kwoco and Equipment Manufacturers

Cooperation Cases Between Kwoco and Equipment Manufacturers KWOCO has become the preferred supplier for an increasing number of equipment manufacturers.