PLC kimenettípusok: Alapvető útmutató automatizálási mérnökök számára

Akár tapasztalt automatizálási szakember, akár csak most kezdi az utat, ez a cikk értékes betekintést nyújt a PLC kimeneti technológiák.

Tartalomjegyzék

Melyek a PLC kimenetek fő típusai és hogyan működnek?

A PLC-kimenetek többféle változatban kaphatók, mindegyiket speciális alkalmazásokhoz és követelményekhez tervezték. A három fő típus a következő:

- Relé kimenetek: Hagyományos elektromechanikus kapcsolókészülékek

- Tranzisztor kimenetek: Szilárdtest kapcsolás DC alkalmazásokhoz

- Triac kimenetek: Szilárdtest kapcsolás váltakozó áramú alkalmazásokhoz

A relé kimenetek a legsokoldalúbbak, mivel AC és DC terhelést is képesek kezelni. Egy tipikus relé kimeneti modul fizikai tekercseket és reléérintkezőket tartalmaz, amelyeket a relé tekercsre feszültség kapcsolásával működtetnek. Például a Allen-Bradley Az 1756-OW16I 16 egyedi relé kimenettel rendelkezik, így alkalmas különféle ipari alkalmazásokra.

Melyek a legfontosabb különbségek a félvezetős és a relé kimenetek között?

A szilárdtest- és relé kimenetek közötti választás több tényezőtől függ:

| Funkció | Szilárdtest-kimenetek | Relé kimenetek |

|---|---|---|

| Kapcsolási sebesség | Gyors (mikroszekundum) | Lassú (ezredmásodperc) |

| Élettartam | Hosszú (mozgó alkatrészek nélkül) | Korlátozott (mechanikai kopás) |

| Feszültség tartomány | AC vagy egyenáramra korlátozva | AC és DC egyaránt |

| Költség | Magasabb kezdeti költség | Alacsonyabb kezdeti költség |

| Karbantartás | Minimális | Rendszeres karbantartás szükséges |

A relékimenetek egyik előnye a feszültségfüggetlenségük, amely lehetővé teszi, hogy AC és DC terhelést is váltsanak anélkül, hogy külön modulra lenne szükségük. A szilárdtest-készülékek azonban jobb megbízhatóságot és hosszabb élettartamot kínálnak a mozgó alkatrészek hiánya miatt.

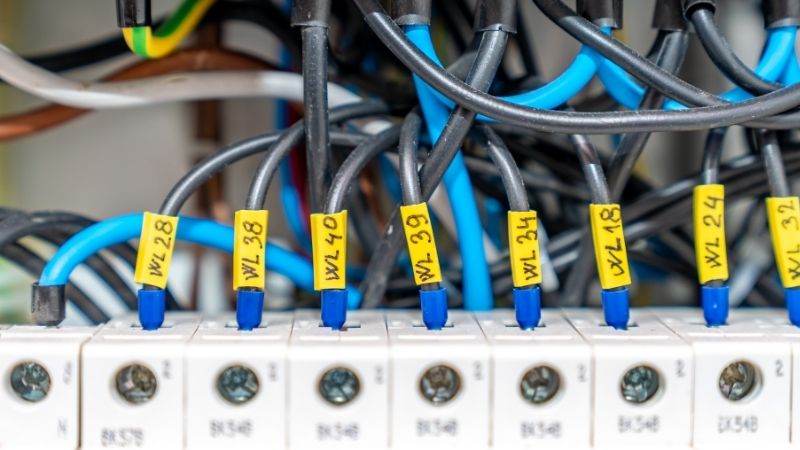

Hogyan kapcsolódnak a digitális kimeneti modulok az ipari berendezésekhez?

A digitális kimeneti modulok interfészként szolgálnak a PLC program és a külső eszközök között. Ezek a modulok vezérelhetik:

- Motorindítók

- Mágnesszelepek

- Jelző lámpák

- Kontaktorok

- Egyéb digitális vagy diszkrét eszközök

A kimeneti modul a PLC program által hozott döntések alapján működik, és ezeket a döntéseket feszültség- vagy áramjeleken keresztül fizikai cselekvésekké alakítja. Például használhat egy kimenetet váltóáramú terhelés kezelésére, egy másik kimenetet pedig egyenáramú terhelés vezérlésére, rugalmas szabályozási lehetőségeket biztosítva.

Mik a fontos szempontok a PLC kimenet kiválasztásánál?

A PLC kimenetek kiválasztásakor vegye figyelembe az alábbi döntő tényezőket:

- Névleges feszültség és áram

- Üzemi feszültség követelményei

- Maximális áramfelvétel

- Túlfeszültség-védelmi igények

- Kapcsolási követelmények

- A váltás gyakorisága

- Terhelés típusa (rezisztív, induktív, kapacitív)

- Válaszidő követelményei

- Környezeti feltételek

- Üzemi hőmérséklet

- Páratartalom szintje

- Elektromos zaj

Melyek a PLC-kimenetekkel kapcsolatos gyakori hibaelhárítási problémák?

A gyakori kimeneti problémák megértése segít fenntartani a rendszer megbízhatóságát:

- A kimenetek rövidzárlat elleni védelme

- A feszültség nagy távolságokon esik le

- A közeli berendezések által okozott interferencia

- Kimeneti modul meghibásodási tünetei

- Megfelelő földelési technikák

Gyakran Ismételt Kérdések

A PLC kimeneti modul a program döntéseit fizikai műveletekké alakítja azáltal, hogy külső eszközöket elektromos jelekkel vezérel.

A választás a terhelési követelményektől és a rendszer kialakításától függ. Az elsüllyedő kimenetek általánosak Észak-Amerikában, míg Európában a beszerzési kimenetek.

A tranzisztoros kimenetek nagyobb kapcsolási sebességet, hosszabb élettartamot és mechanikai kopásmentességet kínálnak, így ideálisak nagy sebességű alkalmazásokhoz.

A relékimenetek előnyben részesíthetők, ha feszültségrugalmasságra van szükség, vagy ha teljes elektromos leválasztásra van szükség a vezérlő és a terhelési áramkörök között.

Használjon megfelelő túlfeszültség-védelmet, gondoskodjon a megfelelő vezetékezésről, tartsa be a megfelelő terhelési értéket, és hajtson végre megfelelő hűtési intézkedéseket.

Erősítse meg projektjeit vadonatúj, eredeti Omron, Mitsubishi, Schneider PLC segítségével – raktáron, készen áll!

Következtetés

- A PLC kimeneteknek három fő típusa van: relé, tranzisztor és triac

- Minden kimeneti típusnak sajátos előnyei és alkalmazásai vannak

- A megfelelő kiválasztás a terhelési követelményektől és a környezeti feltételektől függ

- A rendszeres karbantartás és ellenőrzés biztosítja a megbízható működést

- A védelmi intézkedések elengedhetetlenek a hosszú távú megbízhatósághoz

Új, eredeti PLC-ket keres projektjeihez? A Kwoco-nál a legfrissebb PLC-ket kínáljuk olyan legnépszerűbb márkáktól, mint például Omron, Mitsubishi, és Schneider. Vásároljon bizalommal – gyors szállítás, garantált minőség! Vásároljon most

Lépjen kapcsolatba velünk

Csak töltse ki nevét, e-mail címét és kérésének rövid leírását ezen az űrlapon. 24 órán belül felvesszük Önnel a kapcsolatot.

Ezeket a témákat is érdekesnek találhatja

PLC vs VFD: A programozható logikai vezérlők és a változtatható frekvenciájú meghajtók megértése

Ez a cikk az ipari automatizálás világába nyúlik bele, feltárva a programozható logikai vezérlők (PLC) és a változó frekvenciájú meghajtók (VFD) kulcsfontosságú szerepét. Lebontjuk funkcióikat, összehasonlítjuk erősségeiket és gyengeségeiket, és elmagyarázzuk, hogyan működnek együtt az ipari folyamatok optimalizálása érdekében. Legyen szó gépgyártásról, gyári megoldásokról, vagy egyszerűen csak kíváncsi a modern automatizálásra, ez az útmutató világosan megérti ezeket az alapvető összetevőket.

A miniatűr áramkör-megszakítók (MCB) titkainak feltárása

Ez a cikk a miniatűr áramkör-megszakítók (MCB) lenyűgöző világába nyúlik bele, elmagyarázza az elektromos rendszerek védelmében játszott kulcsfontosságú szerepüket, feltárja működési elvüket, és végigvezeti Önt a rendelkezésre álló különböző típusokon.

Pontosság feloldása: Kódolók és nagy sebességű számlálók masteringje PLC-kkel

Ez a cikk mélyen belemerül a kódolók és a nagy sebességű számlálók (HSC-k) világába, és elmagyarázza, hogyan kapcsolódnak a programozható logikai vezérlőkhöz (PLC), hogy precíz vezérlést biztosítsanak az ipari automatizálási alkalmazásokban. A forgó jeladók megismerésétől a HSC-modulok konfigurálásáig megvizsgáljuk, hogyan működnek együtt ezek a technológiák a sebességszabályozás, a helyzetmérés és a rendszer általános hatékonyságának javítása érdekében.