A Comprehensive Guide to PLC Types and Key Features

Table of Contents

It likewise consists of data-driven comparisons and industry references to aid engineers and decision-makers pick the ideal PLC option for their applications.

Introduction.

In today’s highly automated manufacturing landscape, performance and precision are no longer optional– they are necessary. Programmable Reasoning Controllers (PLCs) , first introduced in the late 1960s, remain among one of the most influential innovations driving industrial control systems.

A PLC is an digital tool created to automate commercial procedures such as equipment control, assembly lines, robotics, and manufacturing facility operations.

It runs by getting input signals from numerous sensors (temperature level, stress, flow, switches, etc), refining them with pre-programmed logic, and afterwards creating output signals to control actuators like motors, valves, or lighting systems.

According to a record from Markets and Markets, the worldwide PLC market dimension is projected to get to USD 15.5 billion by 2027 , driven by clever manufacturing, IoT integration, and Market 4.0 fostering.

Classification of PLCs

PLCs can be categorized in several methods depending on dimension, control method, cpu kind, and application requirements. Below is a structured overview:

| Classification | Categories | Example Use Cases |

| By Scale | Small, Medium, Large | Packaging lines (small), Automotive assembly (medium), Steel plants (large) |

| By Control Mode | Traditional PLC, Fieldbus PLC, Distributed PLC, Smart PLC | Process industries, remote control, intelligent manufacturing |

| By Processor | Microcontroller-based, Microprocessor-based | Low-cost compact systems vs. high-performance systems |

| By Data Handling | Discrete, Analog, Hybrid | Digital signal processing, real-time monitoring |

| By I/O Capacity | Low, Medium, High | Simple machines vs. complex automated plants |

| By Networking | Ethernet-enabled, Bus communication-enabled | Smart factories with real-time monitoring |

This classification illustrates how PLCs are adaptable across industries, from simple conveyor systems to highly integrated smart factories.

Key Features of PLCs

- High Reliability – Designed with robust hardware, PLCs can withstand vibration, electromagnetic interference, and harsh industrial conditions.

- Stable Operation – Once programmed, PLCs maintain consistent performance, ensuring minimal downtime.

- Ease of Programming – With user-friendly programming languages like Ladder Logic and Function Block Diagrams (FBD), engineers can quickly configure systems.

- Modular Maintenance – Components are designed for easy replacement and monitoring, reducing repair times.

- Strong Adaptability – PLCs fit into diverse applications, from discrete manufacturing to process automation.

Market Trends and Technological Innovations

The continual advancement of PLCs is forming the automation industry in extensive means:

- Combination with IoT and Cloud : Modern PLCs are no longer standalone devices but component of a linked ecological community. They allow remote tracking and anticipating upkeep , enhancing effectiveness and lowering costs.

- Miniaturization and Expense Decrease : Developments in microprocessors and microcontrollers have made PLCs a lot more powerful while reducing costs, opening up opportunities for tiny and mid-sized enterprises .

- Cybersecurity Problems : As PLCs integrate with networks, cybersecurity ends up being a critical issue. Makers like Omron and Mitsubishi are embedding stronger safety procedures in their brand-new PLC versions.

PLC vs. Other Control Solutions.

To much better understand the duty of PLCs, allow’s contrast them with traditional relay reasoning and Dispersed Control Solution (DCS):

| Feature | PLC | Relay Logic | DCS |

| Flexibility | High – reprogrammable | Low – requires rewiring | Medium – scalable but costly |

| Cost | Moderate | Low | High |

| Complexity Handling | Excellent | Poor | Excellent |

| Maintenance | Easy | Hard – rewiring needed | Moderate |

| Scalability | High | Very limited | High |

This table shows why PLCs control industrial automation , striking a balance between versatility, performance, and cost.

Real-World Applications

- Automotive Market — Production line automation, robot welding, and quality examinations.

- Food & Beverage — Product packaging, labeling, and procedure control.

- Energy Sector — Power distribution, oil and gas boring, renewable energy combination.

- Pharmaceuticals — Precision dosing, production monitoring, and regulative conformity.

Difficulties and Factors to consider

Despite their advantages, PLCs face difficulties:

- Initial Investment Costs : Larger PLC systems can be pricey.

- Educating Requirements : Engineers need to understand shows languages and procedures.

- Assimilation Complexity : Attaching PLCs with heritage equipment might need added effort.

Nevertheless, with the global shift towards electronic production , these challenges are outweighed by long-lasting efficiency gains.

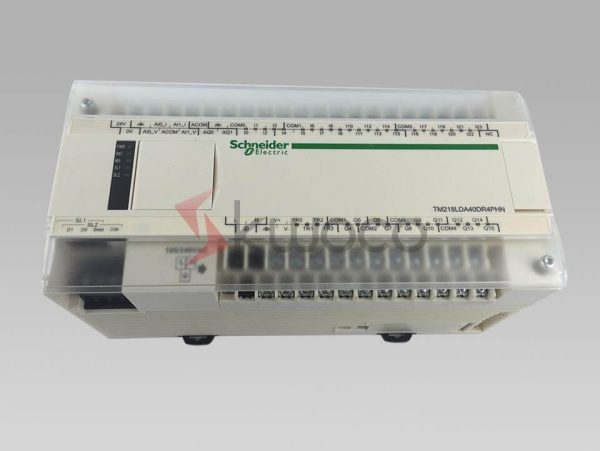

Power your projects with brand-new, original Omron, Mitsubishi, Schneider Servo – in stock, ready now!

Conclusion

PLCs stay the foundation of commercial automation, linking the gap in between equipment dependability and software program versatility. From small-scale packaging lines to massive dispersed systems, PLCs provide scalable, effective, and future-ready remedies .

As Market 4.0 advances, the role of PLCs will expand even more– integrating effortlessly with IoT, AI, and cloud systems to provide clever manufacturing facilities of the future .

Contact Us

Just fill out your name, email address, and a brief description of your inquiry in this form. We will contact you within 24 hours.

Product Category

Hot Sale Products

You May Also Find These Topics Interesting

Mastering SLC500 & ControlLogix PLCs: A Comprehensive Guide

Industrial automation has revolutionized manufacturing, and at the heart of this revolution are Programmable Logic Controllers (PLCs). Among the most prominent are the SLC 500 and ControlLogix series from Rockwell Automation. This comprehensive guide will delve into these controllers, helping you understand their features, applications, and how they can enhance your automation processes.

What is a Level Sensor? Understanding Types and Applications

Level sensors are essential devices in modern industries, ensuring accurate monitoring and measurement of liquid and solid levels. Whether in manufacturing plants, automotive systems, or everyday household appliances, these sensors play a pivotal role in maintaining efficiency and safety.

Understanding Mitsubishi PLC Programming: Languages and Tools

In the fast-evolving world of industrial automation, selecting the right PLC programming language is crucial. Many engineers and technicians grapple with understanding which languages best suit Mitsubishi PLCs and how to effectively utilize them for optimal performance.